The pharmaceutical industry is undergoing a fundamental transformation driven by rising development costs, increasing regulatory expectations, and the growing need for speed to market. As pharmaceutical companies seek to remain competitive while maintaining uncompromised quality, contract manufacturing has emerged as a strategic operating model across global and Indian pharmaceutical markets.

Today, from emerging pharmaceutical startups to established multinational pharmaceutical companies, outsourcing manufacturing operations to specialized partners is no longer just a cost-saving measure. It is a long-term business strategy. In India’s rapidly expanding pharmaceutical ecosystem, contract manufacturing plays a critical role in scaling production, improving operational efficiency, and strengthening supply chain resilience.

This article explores the role of contract manufacturing in pharmaceutical manufacturing, its business relevance, industry benefits, and why India continues to be a preferred destination for global pharmaceutical partnerships.

Understanding Contract Manufacturing in the Pharmaceutical Industry

Contract manufacturing refers to the outsourcing of production activities by a pharmaceutical company to a third-party manufacturer that possesses the required facilities, regulatory certifications, and technical expertise. These specialized manufacturers operate pharmaceutical factories equipped to handle formulation development, scale-up, commercial production, packaging, and in many cases, regulatory documentation.

Unlike traditional in-house production, this model allows companies to leverage established manufacturing infrastructure without making heavy capital investments. In today’s competitive pharmaceutical industry, where innovation cycles are shorter and regulatory requirements are more complex, contract manufacturing offers agility without sacrificing compliance.

The Growing Role of Contract Manufacturing in Pharmaceutical Manufacturing

1. Cost Optimization and Capital Efficiency

Setting up a pharmaceutical factory involves substantial investments in equipment, compliance systems, validation processes, and skilled personnel. For many pharmaceutical manufacturing companies, especially mid-sized and emerging firms, this capital commitment can limit product expansion.

Contract manufacturing enables companies to convert fixed manufacturing costs into variable expenses. By outsourcing production, pharmaceutical companies can focus capital resources on research, regulatory approvals, branding, and market development while manufacturing operations are handled by dedicated specialists.

2. Regulatory Expertise and Compliance

Compliance with national and international regulations is central to pharmaceutical manufacturing. From Schedule M requirements in India to WHO-GMP, USFDA, and EU standards, maintaining regulatory adherence is complex and resource-intensive.

Professional contract manufacturers operate pharmaceutical factories designed to meet stringent compliance benchmarks. This ensures consistent product quality, validated processes, and audit readiness reducing regulatory risk for partnering pharmaceutical companies and hospital procurement teams alike.

3. Faster Time-to-Market

Speed is a decisive factor in the pharmaceutical industry. Whether launching a new formulation or responding to changing market demands, delays in manufacturing can significantly impact business performance.

With established production infrastructure, experienced technical teams, and validated manufacturing lines, contract manufacturers help pharmaceutical companies move from development to commercial supply more efficiently. This is particularly valuable in high-demand segments such as injectables, oral solids, and specialty formulations.

Why India Is a Global Hub for Pharmaceutical Contract Manufacturing

India’s Manufacturing Capabilities

India has emerged as a global leader in pharmaceutical manufacturing, with one of the largest networks of pharmaceutical manufacturing companies worldwide. The country offers:

- A highly skilled technical workforce

- Cost-effective manufacturing operations

- Strong regulatory alignment with global standards

- Extensive experience in exports to regulated and semi-regulated markets

The India pharmaceutical ecosystem is supported by thousands of WHO-GMP-certified pharmaceutical factories capable of handling both large-scale production and specialized manufacturing requirements.

Export-Oriented Manufacturing and Global Reach

Indian contract manufacturers supply to over 200 countries, making India a strategic manufacturing base for pharmaceutical companies seeking international market access. From Africa and Southeast Asia to Europe and Latin America, India’s pharmaceutical manufacturing capabilities support global healthcare supply chains with consistent quality and competitive pricing.

Key Applications of Contract Manufacturing in the Pharmaceutical Industry

Generic and Branded Formulations

Contract manufacturing is widely used for oral solid dosages, liquid formulations, and injectables across therapeutic segments. Pharmaceutical companies can launch multiple product lines without expanding their internal production capacity.

Hospital and Institutional Supply

Hospital procurement teams and healthcare institutions rely on reliable product availability, regulatory compliance, and batch consistency. Contract manufacturing ensures stable supply for institutional markets while meeting strict quality and documentation requirements.

Export-Focused Product Portfolios

Pharmaceutical companies targeting international markets often use Indian contract manufacturers to produce export-ready formulations with the required dossiers, stability data, and regulatory support.

Benefits for Pharmaceutical Distributors and Healthcare Partners

Consistent Quality and Supply Reliability

Contract manufacturing partnerships ensure predictable production schedules and validated quality systems, minimizing supply disruptions for distributors and hospital buyers.

Scalability for Growing Demand

As product demand increases, contract manufacturers can scale operations without requiring additional infrastructure investments from the pharmaceutical company. This flexibility is essential in fast-growing therapeutic categories.

Reduced Operational Complexity

By outsourcing manufacturing, pharmaceutical companies and distributors can focus on market development, logistics, and customer engagement while leaving production to specialized pharmaceutical manufacturing companies.

Choosing the Right Contract Manufacturing Partner

Selecting the right manufacturing partner is critical to long-term success. Pharmaceutical companies should evaluate:

- Regulatory certifications and audit history

- Manufacturing capacity and technological capabilities

- Product development support and technical expertise

- Track record in domestic and international markets

- Supply chain transparency and compliance standards

A reliable contract manufacturing partner functions not just as a supplier, but as an extension of the pharmaceutical company’s operational strategy.

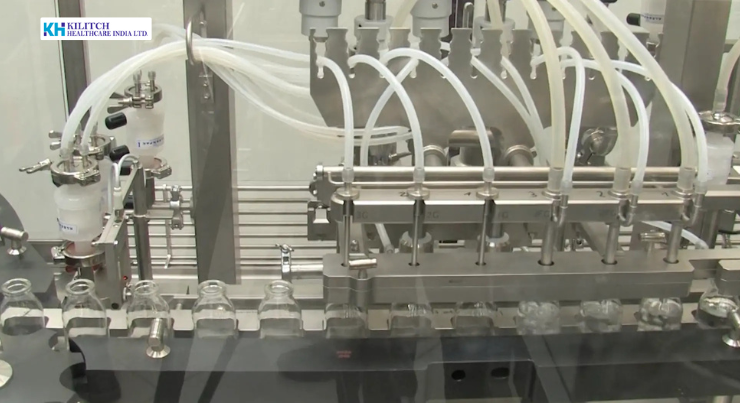

Kilitch Healthcare (KHIL): A Trusted Partner in Pharmaceutical Manufacturing

Within India’s dynamic pharmaceutical industry, Kilitch Healthcare (KHIL) has built a reputation as a dependable partner in pharmaceutical manufacturing. With modern pharmaceutical factory infrastructure and a strong commitment to regulatory compliance, KHIL supports pharmaceutical companies seeking efficient, scalable, and quality-driven contract manufacturing solutions.

By aligning manufacturing excellence with global standards, Kilitch Healthcare enables its partners to expand product portfolios, enter new markets, and maintain consistent quality across therapeutic categories while keeping operations agile and cost-effective.

The Future of Contract Manufacturing in the Pharmaceutical Industry

As healthcare demands evolve and regulatory frameworks become increasingly complex, contract manufacturing will continue to be a cornerstone of pharmaceutical manufacturing strategies. The growing focus on specialized therapies, biologics, and patient-centric formulations further underscores the need for technically advanced manufacturing partners.

For pharmaceutical companies, distributors, and healthcare institutions, contract manufacturing offers a sustainable pathway to growth balancing innovation, compliance, and operational efficiency.

Conclusion: A Strategic Advantage for Modern Pharmaceutical Companies

Contract manufacturing has become an indispensable model in the pharmaceutical industry. By enabling cost efficiency, regulatory assurance, and production scalability, it empowers pharmaceutical companies to remain competitive in both domestic and global markets.

India’s strong pharmaceutical manufacturing ecosystem, combined with reliable partners such as Kilitch Healthcare (KHIL), positions contract manufacturing as a long-term strategic advantage. For pharma distributors, manufacturers, hospital procurement teams, and healthcare professionals, collaborating with the right manufacturing partner ensures consistent quality, dependable supply, and sustainable growth in an increasingly demanding healthcare landscape.For organizations seeking to strengthen their manufacturing strategy while maintaining quality and compliance, contract manufacturing is not just an option. It is a competitive imperative.