Contract Manufacturing in the Pharmaceutical Industry: A Strategic Growth Model for Modern Healthcare

The pharmaceutical industry is undergoing a fundamental transformation driven by rising development costs, increasing regulatory expectations, and the growing need for speed to market. As pharmaceutical companies seek to remain competitive while maintaining uncompromised quality, contract manufacturing has emerged as a strategic operating model across global and Indian pharmaceutical markets. Today, from emerging pharmaceutical startups to established multinational pharmaceutical companies, outsourcing manufacturing operations to specialized partners is no longer just a cost-saving measure. It is a long-term business strategy. In India’s rapidly expanding pharmaceutical ecosystem, contract manufacturing plays a critical role in scaling production, improving operational efficiency, and strengthening supply chain resilience. This article explores the role of contract manufacturing in pharmaceutical manufacturing, its business relevance, industry benefits, and why India continues to be a preferred destination for global pharmaceutical partnerships. Understanding Contract Manufacturing in the Pharmaceutical Industry Contract manufacturing refers to the outsourcing of production activities by a pharmaceutical company to a third-party manufacturer that possesses the required facilities, regulatory certifications, and technical expertise. These specialized manufacturers operate pharmaceutical factories equipped to handle formulation development, scale-up, commercial production, packaging, and in many cases, regulatory documentation. Unlike traditional in-house production, this model allows companies to leverage established manufacturing infrastructure without making heavy capital investments. In today’s competitive pharmaceutical industry, where innovation cycles are shorter and regulatory requirements are more complex, contract manufacturing offers agility without sacrificing compliance. The Growing Role of Contract Manufacturing in Pharmaceutical Manufacturing 1. Cost Optimization and Capital Efficiency Setting up a pharmaceutical factory involves substantial investments in equipment, compliance systems, validation processes, and skilled personnel. For many pharmaceutical manufacturing companies, especially mid-sized and emerging firms, this capital commitment can limit product expansion. Contract manufacturing enables companies to convert fixed manufacturing costs into variable expenses. By outsourcing production, pharmaceutical companies can focus capital resources on research, regulatory approvals, branding, and market development while manufacturing operations are handled by dedicated specialists. 2. Regulatory Expertise and Compliance Compliance with national and international regulations is central to pharmaceutical manufacturing. From Schedule M requirements in India to WHO-GMP, USFDA, and EU standards, maintaining regulatory adherence is complex and resource-intensive. Professional contract manufacturers operate pharmaceutical factories designed to meet stringent compliance benchmarks. This ensures consistent product quality, validated processes, and audit readiness reducing regulatory risk for partnering pharmaceutical companies and hospital procurement teams alike. 3. Faster Time-to-Market Speed is a decisive factor in the pharmaceutical industry. Whether launching a new formulation or responding to changing market demands, delays in manufacturing can significantly impact business performance. With established production infrastructure, experienced technical teams, and validated manufacturing lines, contract manufacturers help pharmaceutical companies move from development to commercial supply more efficiently. This is particularly valuable in high-demand segments such as injectables, oral solids, and specialty formulations. Why India Is a Global Hub for Pharmaceutical Contract Manufacturing India’s Manufacturing Capabilities India has emerged as a global leader in pharmaceutical manufacturing, with one of the largest networks of pharmaceutical manufacturing companies worldwide. The country offers: The India pharmaceutical ecosystem is supported by thousands of WHO-GMP-certified pharmaceutical factories capable of handling both large-scale production and specialized manufacturing requirements. Export-Oriented Manufacturing and Global Reach Indian contract manufacturers supply to over 200 countries, making India a strategic manufacturing base for pharmaceutical companies seeking international market access. From Africa and Southeast Asia to Europe and Latin America, India’s pharmaceutical manufacturing capabilities support global healthcare supply chains with consistent quality and competitive pricing. Key Applications of Contract Manufacturing in the Pharmaceutical Industry Generic and Branded Formulations Contract manufacturing is widely used for oral solid dosages, liquid formulations, and injectables across therapeutic segments. Pharmaceutical companies can launch multiple product lines without expanding their internal production capacity. Hospital and Institutional Supply Hospital procurement teams and healthcare institutions rely on reliable product availability, regulatory compliance, and batch consistency. Contract manufacturing ensures stable supply for institutional markets while meeting strict quality and documentation requirements. Export-Focused Product Portfolios Pharmaceutical companies targeting international markets often use Indian contract manufacturers to produce export-ready formulations with the required dossiers, stability data, and regulatory support. Benefits for Pharmaceutical Distributors and Healthcare Partners Consistent Quality and Supply Reliability Contract manufacturing partnerships ensure predictable production schedules and validated quality systems, minimizing supply disruptions for distributors and hospital buyers. Scalability for Growing Demand As product demand increases, contract manufacturers can scale operations without requiring additional infrastructure investments from the pharmaceutical company. This flexibility is essential in fast-growing therapeutic categories. Reduced Operational Complexity By outsourcing manufacturing, pharmaceutical companies and distributors can focus on market development, logistics, and customer engagement while leaving production to specialized pharmaceutical manufacturing companies. Choosing the Right Contract Manufacturing Partner Selecting the right manufacturing partner is critical to long-term success. Pharmaceutical companies should evaluate: A reliable contract manufacturing partner functions not just as a supplier, but as an extension of the pharmaceutical company’s operational strategy. Kilitch Healthcare (KHIL): A Trusted Partner in Pharmaceutical Manufacturing Within India’s dynamic pharmaceutical industry, Kilitch Healthcare (KHIL) has built a reputation as a dependable partner in pharmaceutical manufacturing. With modern pharmaceutical factory infrastructure and a strong commitment to regulatory compliance, KHIL supports pharmaceutical companies seeking efficient, scalable, and quality-driven contract manufacturing solutions. By aligning manufacturing excellence with global standards, Kilitch Healthcare enables its partners to expand product portfolios, enter new markets, and maintain consistent quality across therapeutic categories while keeping operations agile and cost-effective. The Future of Contract Manufacturing in the Pharmaceutical Industry As healthcare demands evolve and regulatory frameworks become increasingly complex, contract manufacturing will continue to be a cornerstone of pharmaceutical manufacturing strategies. The growing focus on specialized therapies, biologics, and patient-centric formulations further underscores the need for technically advanced manufacturing partners. For pharmaceutical companies, distributors, and healthcare institutions, contract manufacturing offers a sustainable pathway to growth balancing innovation, compliance, and operational efficiency. Conclusion: A Strategic Advantage for Modern Pharmaceutical Companies Contract manufacturing has become an indispensable model in the pharmaceutical industry. By enabling cost efficiency, regulatory assurance, and production scalability, it empowers pharmaceutical companies to remain competitive in both domestic and global markets. India’s strong pharmaceutical manufacturing ecosystem, combined with reliable partners

Sterile Injectable Filling: Precision, Compliance, and Reliability in Modern Pharmaceutical Manufacturing

In contemporary healthcare, sterile injectables are essential for acute care, oncology, anesthesia, critical therapies, and emergency medicine. These dosage forms are delivered directly into the human body, leaving no margin for microbial contamination, particulate matter, or process variability. As a result, sterile injectable filling has become one of the most technically demanding operations within pharmaceutical manufacturing. For pharmaceutical companies, contract manufacturing partners, and quality professionals, the challenge is not only to maintain sterility but to do so consistently, efficiently, and in full compliance with global regulatory expectations. As pharmaceutical manufacturers in India expand their presence in regulated international markets, the precision and reliability of sterile filling operations are increasingly central to both compliance and competitiveness. This article explores the technical fundamentals of sterile injectable filling, the regulatory frameworks that govern it, the technologies that enable it, and the business value it delivers to pharmaceutical stakeholders worldwide. The Technical Importance of Sterile Injectable Filling Sterile filling is the final and most critical stage in the production of injectable medicines. At this point, the product is exposed to the environment and transferred into its primary container vials, ampoules, or prefilled systems making contamination control a top priority. Contamination Control and Aseptic Handling The primary objective of sterile filling is to prevent the introduction of microorganisms, endotoxins, and particulates.This requires: Even minor deviations in air pressure, airflow patterns, or operator behavior can compromise sterility. Therefore, aseptic handling is not merely a procedural requirement; it is a discipline supported by facility design, equipment engineering, and operator training. Precision in Dosage and Product Integrity Beyond sterility, injectable products demand high accuracy in fill volumes. Dosage precision affects drug potency, stability, and therapeutic performance. Variability at micro-level volumes can result in non-compliance, batch rejection, or downstream regulatory scrutiny. In advanced sterile operations, filling accuracy is maintained through calibrated equipment, in-process controls, and real-time monitoring ensuring that every unit meets defined specifications. Compliance and Standards: The Regulatory Framework Behind Sterile Operations Sterile injectable manufacturing is governed by some of the most stringent regulatory standards in the pharmaceutical sector. Adherence to GMP good manufacturing practices is mandatory across all phases of production, from facility design to batch release. Implementing GMP in Sterile Manufacturing Under gmp good manufacturing practices, sterile operations must demonstrate: These systems ensure that sterility is built into the process rather than tested into the final product. For pharmaceutical companies engaged in pharmaceutical contract manufacturing, robust GMP systems are essential to protect brand integrity and regulatory standing. Quality Control Systems and Regulatory Alignment Effective sterile filling is supported by comprehensive quality control for pharmaceutical industry practices. This includes: Facilities that integrate quality into every operational layer are better positioned to meet inspections, audits, and market authorization requirements particularly in export-driven manufacturing models. Equipment and Technology in Sterile Injectable Filling Modern sterile filling operations rely on advanced equipment and automation to reduce human intervention and improve process reliability. Automated Filling and Sealing Systems Automated filling lines are designed to deliver precise volumes under aseptic conditions. Key technical features include: These systems support both high-throughput commercial production and smaller batch manufacturing for specialized therapies. Validation, Monitoring, and Process Control All critical equipment must undergo installation, operational, and performance qualification. Process validation confirms that sterile filling consistently produces output meeting predefined specifications. Advanced monitoring systems track environmental parameters, machine performance, and product attributes in real time. This data-driven approach enhances both compliance and operational transparency key factors for pharmaceutical partners and regulatory bodies alike. Business Benefits of High-Quality Sterile Filling Operations While technical excellence and regulatory compliance are foundational, sterile injectable filling also delivers measurable business value for pharmaceutical companies and healthcare partners. Product Quality and Market Confidence Consistent sterile filling protects product integrity, reduces recalls, and strengthens confidence among healthcare providers and procurement teams. For companies supplying hospitals and institutional markets, this reliability is critical to long-term relationships and repeat business. Scalability and Operational Efficiency Automated and validated sterile filling lines enable manufacturers to scale production without compromising quality. This scalability is particularly valuable for: For pharmaceutical companies leveraging pharmaceutical contract manufacturing, scalability translates into faster time to market and improved supply chain resilience. Cost-Effectiveness Through Process Optimization Although sterile operations require significant infrastructure, optimized workflows and automation reduce waste, rework, and downtime. Over time, these efficiencies improve cost structures making high-quality sterile manufacturing commercially sustainable. Kilitch Healthcare’s Approach to Sterile Injectable Manufacturing Within India’s evolving pharmaceutical landscape, Kilitch Healthcare (KHIL) has developed manufacturing capabilities aligned with global expectations for sterile operations. With dedicated facilities, validated processes, and a quality-driven operating model, KHIL supports pharmaceutical organizations seeking reliable manufacturing partnerships. By integrating advanced equipment, GMP-compliant quality systems, and trained technical teams, Kilitch Healthcare provides: This approach enables pharmaceutical companies to outsource critical manufacturing functions while maintaining confidence in product quality, regulatory readiness, and supply reliability. Strategic Considerations for Pharmaceutical Decision-Makers For QA/QC professionals, regulatory leaders, and operations executives, selecting a sterile manufacturing partner is a strategic decision with long-term implications. Key evaluation criteria include: As pharmaceutical manufacturers in India continue to strengthen their global footprint, partnerships built on technical rigor and compliance excellence will define competitive advantage. Conclusion: Strengthening Pharmaceutical Manufacturing Through Sterile Excellence Sterile injectable filling represents the intersection of precision engineering, regulatory compliance, and patient safety. In a healthcare environment where injectable therapies are indispensable, the quality of sterile manufacturing directly influences clinical outcomes and brand credibility. By investing in advanced technology, robust quality systems, and disciplined operational practices, pharmaceutical companies can ensure that every unit delivered to the market meets the highest standards of safety and performance. With its focus on compliance, scalability, and technical integrity, Kilitch Healthcare (KHIL) exemplifies the capabilities required for dependable sterile manufacturing in both Indian and global markets. For organizations seeking a trusted partner in pharmaceutical manufacturing one that combines regulatory discipline with operational excellence sterile injectable filling is not just a process, but a strategic capability To explore partnership opportunities or discuss manufacturing requirements, connect with Kilitch Healthcare’s technical team.

Why Eye Care Specialists Recommend Haloeye Ultra Sodium Hyaluronate Eye Drops for Dry Eyes

Why Eye Care Specialists Recommend Haloeye Ultra Sodium Hyaluronate Eye Drops for Dry Eyes Dry eye symptoms (Haloeye Ultra Sodium Hyaluronate Eye Drops for Dry Eyes) have become increasingly common in modern lifestyles. Extended screen time, air-conditioned environments, pollution, contact lens use, and aging all contribute to reduced tear quality and eye surface irritation. What often begins as mild discomfort can gradually affect visual clarity and daily productivity if not managed properly. For these reasons, eye care specialists emphasize the importance of clinically reliable lubricating eye drops. Among the options available, Haloeye Ultra Sodium Hyaluronate Eye Drops for Dry Eyes are widely recommended for their advanced formulation, long-lasting comfort, and suitability for regular use. Dry Eyes: A Growing Clinical Concern Healthy eyes rely on a stable tear film to maintain moisture, protect against irritants, and support clear vision. When tear production decreases or evaporation increases, the eye surface becomes vulnerable. Common symptoms include dryness, burning, redness, foreign body sensation, and visual fatigue. Left untreated, chronic dry eye can disrupt daily activities and may lead to inflammation of the ocular surface. This is why specialists prefer eye drops that do more than provide temporary relief — they look for solutions that support tear film stability and ocular surface health. Why Sodium Hyaluronate Is Preferred by Specialists Sodium hyaluronate is a naturally occurring substance found in the human eye and connective tissues. Its primary advantage lies in its exceptional water-retention ability. When used in ophthalmic formulations, it helps attract and hold moisture on the eye surface. Unlike basic lubricants that wash away quickly, sodium hyaluronate forms a smooth, viscoelastic layer that remains on the eye for longer durations. This allows for continuous lubrication with each blink, reducing friction and discomfort. Because it closely mimics natural tears, eye care specialists trust sodium hyaluronate for both comfort and safety in dry eye management. What Makes Haloeye Ultra a Reliable Choice Haloeye Ultra Sodium Hyaluronate Eye Drops for Dry Eyes are designed to deliver consistent hydration while maintaining a gentle feel. Eye care professionals often recommend this formulation due to several practical benefits: These features make Haloeye Ultra suitable for individuals experiencing digital eye strain, environmental dryness, or contact lens–related discomfort. Recommended Use in Daily Eye Care Eye care specialists typically advise using Preservative Free lubricating eye drops like Haloeye Ultra regularly rather than only when symptoms become severe. Applying the drops as recommended helps maintain consistent eye hydration, especially during extended screen exposure or in dry indoor environments. Proper hygiene while instilling the drops and adherence to professional guidance ensure maximum benefit and eye safety. Eyekarekilitch: Focused Expertise in Ophthalmic Solutions Eyekarekilitch is a specialized division of Kilitch Healthcare, dedicated exclusively to eye care and ophthalmic formulations. The division focuses on addressing evolving eye health needs through scientifically developed, quality-driven products. With strong pharmaceutical expertise and a commitment to ocular safety, Eyekarekilitch designs eye care solutions that align with clinical expectations and patient comfort. Products such as Haloeye Ultra Sodium Hyaluronate Eye Drops for Dry Eyes reflect this approach — combining research-backed ingredients with careful formulation standards. As part of Kilitch Healthcare, Eyekarekilitch continues to support eye care specialists with dependable products tailored for modern ocular challenges. Conclusion: A Clinically Trusted Solution for Dry Eyes Managing dry eyes effectively requires more than temporary relief. It calls for products that support the natural tear film, protect the ocular surface, and provide lasting comfort. Eye care specialists recommend Haloeye Ultra Sodium Hyaluronate Eye Drops for Dry Eyes because they offer a balanced combination of hydration, lubrication, and gentle care. Whether dryness is caused by digital strain, environmental exposure, or contact lens use, Haloeye Ultra provides a professional, reliable solution for everyday eye comfort.

Post-Surgery Eye Care: How Haloeye Ultra Sodium Hyaluronate Eye Drops Support Healing

Post-Surgery Eye Care: How Haloeye Ultra Sodium Hyaluronate Eye Drops Support Healing Undergoing eye surgery is an important step toward restoring or improving vision. Procedures such as cataract surgery, LASIK, glaucoma interventions, or corneal treatments are designed to enhance eye health—but the success of these procedures depends greatly on how well the eyes are cared for afterward. Post-surgery eye care (Haloeye Ultra Sodium Hyaluronate Eye Drops) is not just about following instructions; it’s about giving the eyes the right environment to heal safely and comfortably. One of the most commonly recommended elements of post-operative care is the use of high-quality Preservative Free lubricating eye drops. Among these, Haloeye Ultra Sodium Hyaluronate Eye Drops play a valuable role in supporting healing, maintaining moisture, and improving overall comfort during recovery. Understanding the Challenges After Eye Surgery After eye surgery, it is normal for patients to experience symptoms such as dryness, foreign-body sensation, mild burning, redness, or fluctuating vision. These symptoms occur because surgical procedures can temporarily disturb the natural tear film and the sensitive surface of the eye. The tear film is essential for: When this tear balance is disrupted, the eyes become vulnerable to irritation and delayed recovery. This is why ophthalmologists emphasize the use of advanced lubricating eye drops as part of a structured post-surgery care plan. Why Sodium Hyaluronate Is Essential for Post-Operative Eye Care Sodium hyaluronate is a naturally occurring substance found in the human body, including the eyes. It is known for its exceptional ability to bind and retain water, making it a key ingredient in modern ophthalmic formulations. In post-surgical eye care, sodium hyaluronate offers several advantages: Because of these properties, sodium hyaluronate closely mimics natural tears, making it especially suitable for sensitive, healing eyes. How Haloeye Ultra Sodium Hyaluronate Eye Drops Support Healing Haloeye Ultra Sodium Hyaluronate Eye Drops are formulated with a higher concentration of sodium hyaluronate, providing long-lasting lubrication and comfort. These drops are designed to meet the needs of patients recovering from eye surgery, as well as those experiencing moderate to severe dryness. Key Benefits of Haloeye Ultra Sodium Hyaluronate Eye Drops 1. Long-Lasting MoistureHaloeye Ultra forms a stable, protective layer over the ocular surface, helping to maintain consistent hydration throughout the day. This reduces the need for frequent application and improves patient compliance. 2. Enhanced Post-Surgical ComfortBy soothing irritation and minimizing dryness, the drops help relieve common post-operative symptoms such as burning, grittiness, and eye fatigue. 3. Support for Natural HealingA well-hydrated ocular surface promotes healthy epithelial regeneration, which is critical after surgical procedures. Haloeye Ultra helps create optimal conditions for faster and smoother recovery. 4. Gentle and Well-ToleratedThe formulation is suitable for sensitive eyes and can be safely used as part of a doctor-recommended post-surgery regimen. Because of these benefits, Haloeye Ultra Sodium Hyaluronate Eye Drops are often recommended following procedures such as cataract surgery, refractive surgery, and other ophthalmic interventions. Best Practices for Using Eye Drops After Surgery To get the maximum benefit from post-surgery eye drops, patients should follow proper usage guidelines: Following these steps ensures both safety and effectiveness during the healing period. The Role of Eyekarekilitch in Advanced Eye Care Eyekarekilitch is the dedicated ophthalmic division of Kilitch Healthcare India Ltd., a well-established pharmaceutical company with a strong reputation for quality and innovation. Eyekarekilitch focuses exclusively on eye health, offering a comprehensive range of ophthalmic solutions designed to meet the evolving needs of patients and healthcare professionals. With a commitment to research-driven development and stringent quality standards, Eyekarekilitch delivers products that combine safety, efficacy, and patient comfort. Their portfolio addresses a wide spectrum of eye care needs, from dry eye management and post-operative support to specialized therapeutic solutions. Products like Haloeye Ultra Sodium Hyaluronate Eye Drops reflect Eyekarekilitch’s focus on advanced formulations that support better outcomes in everyday clinical practice. Conclusion Successful eye surgery doesn’t end with the procedure—it continues through careful, consistent post-operative care. Maintaining a healthy, well-lubricated ocular surface is essential for comfort, protection, and proper healing. Haloeye Ultra Sodium Hyaluronate Eye Drops offer reliable hydration, gentle relief, and effective support during the recovery phase. Backed by the expertise of Eyekarekilitch, these eye drops are a trusted choice for post-surgery eye care, helping patients move toward clearer vision and long-term eye health with confidence.

Sodium Hyaluronate Drops: Global Market Trends and Growing Demand in Modern Eye Care

Sodium Hyaluronate Drops: Global Market Trends and Growing Demand in Modern Eye Care Eye care has emerged as a critical component of overall health as modern lifestyles place increasing strain on visual systems. Extended screen exposure, environmental pollution, aging populations, and rising awareness about ocular wellness are reshaping the global ophthalmic landscape. At the center of this transformation are Sodium Hyaluronate Drops, widely regarded as one of the most effective solutions for ocular lubrication and dry eye management. As demand grows across both developed and emerging markets, sodium hyaluronate–based eye drops are gaining prominence among clinicians, patients, and healthcare manufacturers alike. What Makes Sodium Hyaluronate Drops Essential in Eye Care? Sodium hyaluronate is a naturally occurring biopolymer derived from hyaluronic acid, known for its exceptional water-binding and viscoelastic properties. When formulated as ophthalmic drops, it closely mimics the natural tear film, helping maintain moisture on the ocular surface for extended periods. Unlike conventional lubricants, sodium hyaluronate eye drops provide: These properties make sodium hyaluronate drops particularly effective for conditions such as dry eye disease, post-surgical eye care, contact lens–related discomfort, and digital eye strain. Global Market Overview: A Rapidly Expanding Segment The global market for Sodium Hyaluronate Drops has shown consistent growth over the past decade and is expected to expand steadily in the years ahead. This growth reflects a shift toward advanced, patient-friendly ophthalmic formulations that prioritize safety, efficacy, and long-term ocular health. Key Market Growth Drivers Several factors are fueling the increasing demand for sodium hyaluronate ophthalmic solutions: Together, these trends have positioned sodium hyaluronate drops as a preferred option in both prescription and over-the-counter eye care segments. Technological Advancements Shaping the Market Innovation continues to play a crucial role in the evolution of sodium hyaluronate eye drops. Manufacturers are focusing on refining formulations to enhance patient comfort and therapeutic outcomes. Notable advancements include: These developments are expanding the clinical applications of sodium hyaluronate drops while improving patient adherence and satisfaction. Regional Market Insights Asia-Pacific: Fastest-Growing Market The Asia-Pacific region represents a major growth engine for sodium hyaluronate eye drops. Countries such as India, China, and Japan are witnessing increased demand driven by urbanization, rising screen exposure, and expanding access to ophthalmic care. Growing investments in pharmaceutical manufacturing and healthcare infrastructure further support market expansion in this region. North America and Europe: Established and Innovation-Driven In North America and Europe, the market is characterized by advanced formulations, strong regulatory standards, and high awareness among eye care professionals. The demand here is largely driven by aging populations, post-operative eye care needs, and a strong preference for clinically proven ophthalmic solutions. Eyekarekilitch: Advancing Ophthalmic Solutions Eyekarekilitch is a dedicated ophthalmic division of Kilitch Healthcare, focused on delivering high-quality, science-driven eye care products to meet evolving clinical and patient needs. Backed by Kilitch Healthcare’s strong pharmaceutical expertise and global presence, Eyekarekilitch is committed to innovation, quality, and therapeutic reliability. The division emphasizes: Within its ophthalmic portfolio, sodium hyaluronate-based eye drops play a significant role, offering reliable hydration and comfort for patients experiencing dry eye symptoms, ocular irritation, and environmental stress. By combining research-led development with patient-centric design, Eyekarekilitch contributes meaningfully to the growing global demand for effective eye care therapies. Future Outlook: Sustained Demand and Market Opportunity The future of the sodium hyaluronate eye drops market remains strong. As eye health becomes a global priority, demand will continue to rise for formulations that are safe, effective, and suitable for long-term use. Increasing digitalization, lifestyle-related eye disorders, and expanding healthcare access will further reinforce the market’s growth trajectory. Manufacturers that invest in innovation, preservative-free technologies, and patient-focused solutions are well positioned to lead the next phase of ophthalmic care advancement. Conclusion Sodium Hyaluronate Drops have become an integral part of modern eye care, addressing both clinical needs and lifestyle-related ocular challenges. Their proven effectiveness, excellent tolerability, and growing global acceptance make them a cornerstone of contemporary ophthalmic therapy. With divisions like Eyekarekilitch, under the umbrella of Kilitch Healthcare, contributing to innovation and quality-driven development, the future of sodium hyaluronate eye care solutions looks both sustainable and impactful. As awareness grows and technology advances, these formulations will continue to redefine standards in eye comfort and ocular health management.

Why Kilitch Healthcare Eye Drops Manufacturer In India Leads the Ophthalmic Industry

Why Kilitch Healthcare Eye Drops Manufacturer In India Leads the Ophthalmic Industry The ophthalmic pharmaceutical segment demands the highest levels of precision, safety, and scientific expertise. Eye drops, in particular, require strict adherence to quality standards due to their direct application to sensitive ocular tissues. In this highly regulated and competitive environment, Kilitch Healthcare has emerged as a leading eye drops manufacturer in India, consistently delivering reliable, effective, and patient-centric ophthalmic solutions. With a strong legacy in pharmaceutical manufacturing and a forward-looking approach to innovation, Kilitch Healthcare continues to play a defining role in shaping the ophthalmic industry both domestically and internationally. Advanced Manufacturing Infrastructure and Quality Assurance Kilitch Healthcare’s success as an eye drops manufacturer is rooted in its advanced manufacturing infrastructure. The company operates state-of-the-art, WHO-GMP–compliant production facilities designed specifically for ophthalmic formulations. These facilities are equipped with controlled environments, automated filling lines, and stringent sterility protocols to ensure product safety and consistency. Each batch undergoes rigorous in-process and final quality checks, including sterility testing, stability analysis, and packaging validation. This meticulous approach ensures that every product meets regulatory requirements and delivers consistent therapeutic performance, reinforcing Kilitch Healthcare’s credibility in the ophthalmic space. Leadership in Preservative Free Eye Drops As awareness around ocular sensitivity and long-term eye health grows, the demand for preservative free eye drops has increased significantly. Kilitch Healthcare has proactively addressed this shift by developing advanced preservative-free ophthalmic formulations that minimize irritation while maintaining product stability and efficacy. These formulations are particularly beneficial for patients with chronic dry eye, post-surgical conditions, contact lens users, and individuals with sensitive eyes. By focusing on preservative-free solutions, Kilitch Healthcare demonstrates a deep understanding of evolving patient needs and clinical preferences, positioning itself as a progressive and responsible manufacturer. Comprehensive Ophthalmic Product Portfolio Kilitch Healthcare offers a diverse range of ophthalmic products designed to address multiple eye care indications. The company’s portfolio includes lubricating and moisturizing eye drops, anti-infective solutions, anti-inflammatory formulations, and supportive therapies for post-operative care. This wide product range allows Kilitch Healthcare to serve ophthalmologists, hospitals, and healthcare providers with reliable solutions across therapeutic categories. Its ability to deliver both standard and specialized formulations further strengthens its standing as a dependable eye drops manufacturer in India. Eyekare Kilitch: A Dedicated Division for Ophthalmic Excellence Eyekare Kilitch is the specialized ophthalmic division of Kilitch Healthcare, created with a singular focus on eye care innovation and quality. This subdivision represents the brand’s strategic commitment to advancing ophthalmic solutions through dedicated research, formulation expertise, and market-driven product development. Eyekare Kilitch concentrates exclusively on eye drops and related ophthalmic products, including preservative-free options developed to meet modern clinical standards. By operating as a focused division, Eyekare Kilitch ensures greater attention to detail, faster innovation cycles, and enhanced responsiveness to ophthalmologists’ and patients’ needs. This dedicated approach significantly contributes to Kilitch Healthcare’s leadership in the ophthalmic industry. Strong Emphasis on Research, Development, and Compliance Research and development play a critical role in Kilitch Healthcare’s growth and industry leadership. The company continuously invests in improving formulations, enhancing delivery systems, and adopting advanced packaging technologies that support product safety and ease of use. Equally important is Kilitch Healthcare’s commitment to regulatory compliance. Strict adherence to national and international guidelines ensures smooth approvals, reliable documentation, and long-term product credibility in both domestic and export markets. Global Reach and Trusted Partnerships Beyond India, Kilitch Healthcare has established a strong presence in international markets through exports and strategic partnerships. Its reputation as a reliable eye drops manufacturer is built on consistent quality, transparent operations, and timely supply capabilities. Healthcare institutions, distributors, and pharmaceutical partners value Kilitch Healthcare for its professionalism, technical expertise, and long-term reliability, making it a preferred partner in the global ophthalmic supply chain. Conclusion Kilitch Healthcare’s leadership in the ophthalmic industry is the result of a well-balanced combination of manufacturing excellence, scientific expertise, and patient-focused innovation. As a trusted eye drops manufacturer in India, the company continues to raise industry standards through high-quality formulations, a strong focus on preservative free eye drops, and the dedicated efforts of its ophthalmic division, Eyekare Kilitch. With a clear vision for the future and an unwavering commitment to eye health, Kilitch Healthcare remains at the forefront of ophthalmic pharmaceutical manufacturing, delivering solutions that healthcare professionals and patients can rely on with confidence.

Best Sodium Hyaluronate Eye Drops for Computer Vision Syndrome

Best Sodium Hyaluronate Eye Drops for Computer Vision Syndrome Spending long hours in front of computers, laptops, and smartphones has become a daily reality for professionals, students, and even children. While digital devices improve productivity, they also bring a growing eye health concern—Computer Vision Syndrome (CVS). Symptoms such as dryness, irritation, blurred vision, eye strain, and burning sensations are now increasingly common. One of the most trusted solutions recommended by eye care professionals is Best sodium hyaluronate eye drops. In this article, we explore how sodium hyaluronate helps relieve digital eye strain and what to look for when choosing the best sodium hyaluronate eye drops for Computer Vision Syndrome. Understanding Computer Vision Syndrome Computer Vision Syndrome is a group of eye and vision-related problems caused by prolonged digital screen use. When we focus on screens, our blink rate drops significantly, leading to faster tear evaporation and dry eyes. Over time, this dryness can cause discomfort, redness, and reduced visual clarity. Common CVS symptoms include: Managing these symptoms early is essential to prevent long-term eye discomfort. Why Sodium Hyaluronate Is Effective for Digital Eye Strain Sodium hyaluronate is a naturally occurring substance found in the human eye. It plays a key role in maintaining moisture and lubrication on the ocular surface. When used in eye drops, it offers several benefits that make it ideal for people suffering from Computer Vision Syndrome. Key benefits of sodium hyaluronate eye drops: Because of its viscoelastic nature, sodium hyaluronate stays longer on the eye surface compared to ordinary lubricants, offering sustained relief. What Makes the Best Sodium Hyaluronate Eye Drops? Not all eye drops are the same. When selecting the best sodium hyaluronate eye drops for Computer Vision Syndrome, it’s important to consider certain quality factors. 1. Optimal Concentration Eye drops typically contain sodium hyaluronate in concentrations ranging from 0.1% to 0.3%. Lower concentrations are suitable for mild dryness, while higher concentrations provide deeper hydration for moderate to severe digital eye strain. 2. Preservative-Free or Gentle Preservatives Frequent screen users may need to apply eye drops multiple times a day. Preservative-free formulations are ideal, especially for sensitive eyes, as they reduce the risk of irritation with long-term use. 3. Long-Lasting Comfort The best sodium hyaluronate eye drops should provide prolonged relief without causing blurring or sticky residue, allowing users to continue work comfortably. 4. Compatibility with Contact Lenses Many digital users also wear contact lenses. Choosing drops that are safe for contact lens wear adds extra convenience. How Sodium Hyaluronate Eye Drops Help CVS Patients For individuals experiencing computer-related eye discomfort, sodium hyaluronate eye drops work by restoring the natural tear balance. They form a protective, moisturizing layer over the cornea, reducing dryness caused by reduced blinking. With regular use, users often notice: This makes sodium hyaluronate-based solutions a preferred choice for office workers, IT professionals, gamers, and students. Final Thoughts Computer Vision Syndrome is no longer limited to office environments—it affects anyone who spends extended hours on digital devices. Choosing the best sodium hyaluronate eye drops for Computer Vision Syndrome is a practical and reliable way to protect eye health and maintain daily comfort. With their natural compatibility, long-lasting hydration, and proven effectiveness, sodium hyaluronate eye drops remain a gold standard solution for digital eye strain. Investing in the right formulation today can help ensure healthier, more comfortable eyes tomorrow—no matter how screen-focused your lifestyle may be.

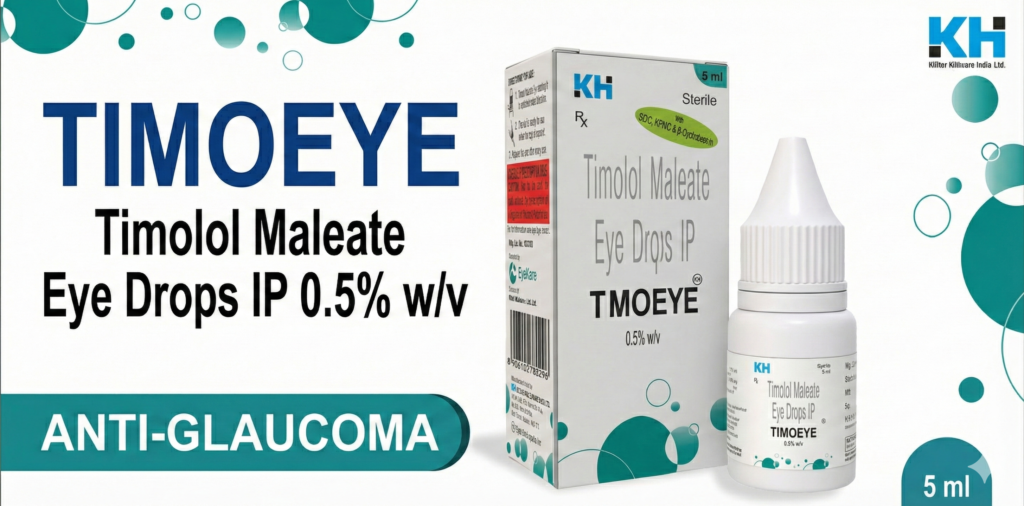

How Brimonidine Tartrate and Timolol Maleate Eye Drops Help Control Eye Pressure

How Brimonidine Tartrate and Timolol Maleate Eye Drops Help Control Eye Pressure Maintaining healthy eye pressure is one of the most important steps in protecting long-term vision. For individuals living with glaucoma or ocular hypertension, even slightly elevated intraocular pressure (IOP) can gradually damage the optic nerve and lead to permanent vision loss if not managed properly. This is why ophthalmologists often rely on proven combination therapies such as Brimonidine Tartrate and Timolol Maleate Eye Drops to achieve consistent and effective pressure control. This blog takes a closer look at how these eye drops work, why they are prescribed together, and how they fit into a comprehensive approach to glaucoma management. Why Eye Pressure Control Is So Important Intraocular pressure refers to the pressure created by the fluid (aqueous humor) inside the eye. Under normal conditions, this fluid is continuously produced and drained to maintain a healthy balance. When drainage slows down or fluid production increases, pressure begins to rise. Persistently high eye pressure is the most significant risk factor for glaucoma, a condition that often progresses silently without noticeable symptoms in its early stages. Once vision loss occurs, it cannot be reversed. Effective and timely pressure control is therefore essential to slow disease progression and preserve eyesight. An Overview of Brimonidine Tartrate and Timolol Maleate Eye Drops Brimonidine Tartrate and Timolol Maleate Eye Drops combine two well-established glaucoma medications into a single formulation. Each component works differently, making the combination more effective than using either drug alone. By targeting eye pressure from two different pathways, this combination delivers reliable and sustained IOP reduction. How Brimonidine Tartrate Lowers Eye Pressure Brimonidine Tartrate plays a dual role in managing intraocular pressure: This dual action makes Brimonidine particularly useful for maintaining stable eye pressure throughout the day, including during peak pressure hours. The Role of Timolol Maleate in Eye Pressure Management Timolol Maleate works by addressing the source of eye pressure: By blocking beta receptors in the ciliary body, Timolol significantly lowers aqueous humor production. This results in a steady decrease in intraocular pressure and helps prevent pressure spikes that can accelerate optic nerve damage. Timolol is often considered a foundational treatment in glaucoma care due to its proven effectiveness and predictable results. Why Combination Therapy Works Better for Many Patients Using Brimonidine Tartrate and Timolol Maleate Eye Drops together offers several practical and clinical benefits: For patients whose eye pressure is not adequately controlled with a single medication, combination therapy often provides a more dependable solution. Who Is Typically Prescribed These Eye Drops? Ophthalmologists commonly recommend this combination for: As with any prescription treatment, suitability depends on individual health factors and should always be assessed by an eye care professional. Proper Use and Patient Compliance The effectiveness of Brimonidine Tartrate and Timolol Maleate Eye Drops depends heavily on correct and consistent use. Missing doses or improper application can reduce pressure control and increase the risk of disease progression. Key usage tips include: Patients should promptly report any discomfort or unusual symptoms to their ophthalmologist. Supporting Long-Term Vision Health Glaucoma is a chronic condition that requires ongoing management. While medication cannot cure the disease, effective treatments like Brimonidine Tartrate and Timolol Maleate Eye Drops play a vital role in slowing its progression. When combined with regular eye examinations, lifestyle awareness, and early intervention, these eye drops help protect the optic nerve and support long-term visual stability. Many patients are able to maintain their quality of life and independence with proper adherence to treatment. Final Thoughts Brimonidine Tartrate and Timolol Maleate Eye Drops represent a well-balanced and clinically trusted approach to controlling elevated eye pressure. By combining two complementary medications into one convenient formulation, they offer enhanced efficacy, better compliance, and reliable long-term results. For patients and healthcare providers seeking an effective solution for glaucoma and ocular hypertension management, this combination therapy continues to be a cornerstone of modern ophthalmic care. Eyekare Kilitch Ltd – Your Vision is Our Focus At EyeKare, we are deeply committed to ophthalmology. We have emerged as a niche leader offering a comprehensive range of ophthalmic solutions that cover virtually all therapeutic areas. Kilitch Healthcare is an innovative pharmaceutical company that discovers, develop, manufactures and market a broad range of healthcare products under the name of its various group companies.